Local curriculum design in year 12: Manufacturing predator traps

Students helping to protect their local ecosystem

At Wakatipu High School, Year 12 students are manufacturing predator traps for Predator Free NZ as part of their hard materials programme. This is an example of local curriculum design.

The Predator Free 2050 programme

Getting rid of damaging predators

The goal of the Predator Free 2050 programme is to rid New Zealand of rats, weasels, stoats, possums, and hedgehogs by 2050.

These are the most damaging mammalian predators that threaten New Zealand’s natural taonga, economy, and the primary sector.

This technology programme brings together central and local government, iwi, philanthropists, non-government organisations such as Predator Free NZ, businesses, science and research organisations, communities, landowners, and individuals with the students' learning through the school's local curriculum design.

Local curriculum

Local Curriculum Guide series

The Leading Local Curriculum Guide series suggest that two of the high impact practices when designing and reviewing curriculum are:

- enabling relationships for learning

- providing rich opportunities for learning.

The Wakatipu community

In line with the focus on local curriculum, teacher Rebecca Lund sees real merit in selecting contexts for students that recognise local community issues.

A local community context provides opportunities for students to interact and build relationships for learning with people working within the community. Wakatipu Wildlife Trust was very interested in the students manufacturing the traps.

This project encouraged students to contribute and support beneficial outcomes for the community they belong to.

Rich opportunities for learning

Learning about local ecosystems, measurement, physics, and design

Learning about local ecosystems, measurement, physics, and design

The manufacturing traps project provided rich opportunities for learning.

The students learnt about the predator free programme and local ecosystems. Many students were surprised to learn how destructive hedgehogs are for local native bird life (because they feed on the eggs of native birds). They also learned which baits appealed to each animal. For example, rats love peanut butter and hedgehogs love eggs.

The students were shown the GPS system used by predator free groups to locate the position of their traps. For more information, see TRAP.NZ.

The predator trap was also an opportunity to learn about accurate measurement and the physics of the trap design.

Predator traps can be an opportunity to explore the characteristics of technological outcomes component of the nature of technology strand. The accurate measurement and physics can lead to discussions on if the traps are fit for purpose in their context and understanding the concept of malfunction.

Making the traps

The brief and specifications

Each student initially made a DOC 200 trap to the brief and specifications provided by DOC.

Measurements

Lee Hiestand, head of learning mathematics at Wakatipu High School manages the Wakatipu High School predator free trapping line. She was able to act as a stakeholder and discuss with the students the importance of accurate measurement to meet the specifications shown on the drawings. This would ensure that the traps caught the predators.

Modifications

The students also made some modifications to the trap. One modification was to embed a different type of screw in the lids to prevent screw heads stripping out from traps continually being opened.

The stakeholders asked if they could design a system so that they could visually check the trap rather than having to get down on their hands and knees and check inside every trap to see whether it needed to be reset.

The students designed an indicator tab that could be seen on the outside of the trap when walking past the trap. If the trap went off the indicator tab was pulled inside by the trap mechanism.

The students also designed their own logo so that their traps were easily identifiable for checking and resetting.

For other information on these traps see: DOC 200 predator traps.

Next steps

Feedback from stakeholders

Stakeholders have been very pleased with the workmanship and accuracy of the traps made by the students. Trapping groups have had issues in the past with traps not being made accurately to specifications. This meant the traps did not work in situ. Inaccuracies can also alter the effectiveness in terms of humane kills. The way in which an animal enters the trap and kill area is critical for safe and humane function.

Establishing a manufacturing system and setting traps

The next step is that each student is going to establish a manufacturing system and manufacture three traps which they will set and monitor every one to two weeks. The students have been trained to set the traps, to follow health and safety procedures when doing this, and also how to safely remove the predators. Placement and bait requirements are important for maximum effectiveness. The students have learnt about different bait requirements. Wiping the trap with the dead rodent will attract other predators as they often go where they can smell where other predators have been.

Rebecca has planned a field trip to set the traps for a day and would also like the students to learn about other types of traps used by DOC for trapping different predators.

Assessment and evidence

Documenting evidence

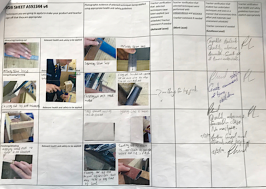

Students are required every week to complete a printed A3 sheet showing their progress in the project. The students are encouraged to annotate their photographs to demonstrate their understanding of the photographs' significance.

As recommended in the NZQA technology clarifications teacher observations are also collected for AS 91344: Implement advanced procedures using resistant materials to make a specified product with special features.

Rebecca is also investigating other tools and strategies to support students in documenting evidence of practice, for example:

- Using iCoach to record evidence in furniture-making

- Voice typing in Google Docs

- Assessment tools and approaches

NCEA achievement standards

Learning in this authentic context can be assessed against the following NCEA level 2 standards:

- AS 91344 Implement advanced procedures using resistant materials to make a specified product with special features

- AS 91366 Undertake development and implementation of an effective manufacturing process.

Rebecca is also looking at the requirements to enable the students to use their evidence for learning in this project to be assessed against the following education for sustainability NCEA standard: