Sustainability: Domestic energy efficiency

Teaching inquiry

How could I get senior technology students interested in sustainable energy design and supply? Could we develop solar water / photovoltaic systems that are cheap enough to become a low-cost solution for every day NZ householders?

Introduction

Teacher Dave Dobbin found that the context of researching, designing, and building energy efficient solar water heating systems:

- challenged and engaged the students

- grew students’ awareness and understanding of sustainability in technology

- increased students’ understandings within all three strands of technology

- developed students’ generic technology understandings and specific construction skills

- provided access for students to both university and apprenticeship vocational pathways.

Background

Dave Dobbin at Trident High School comes from a background of working in energy. One of Dave’s jobs was with Energy Options, a company owned by Eastern Bay Energy Trust (EBET), where he worked as an engineer to design domestic energy efficient water and space heating solutions. Dave has a passion for, and knowledge of, a range of technologies in this field – but more importantly he wants to see more young people excited by this field of technology.

In the past, the metal workshop programme at Trident High School only went up to year 12. Dave could see he needed a year 13 programme and that this would be an ideal opportunity to introduce the context of energy efficiency.

I wanted to have some fun with solar heating and sustainability.

Dave Dobbin

Managing costs

Dave’s previous employer EBET has provided a $4000 grant for the programme each year.

They like our programme, as it is unique in schools and they want more schools to pick this up. It also encourages students to join the energy industry for which they provide scholarships for tertiary study.

Dave Dobbin

Dave uses the grant to cover all student fees, materials, tools, and equipment specific to this programme. So far, students have not had to pay any fees for the programme. This has provided an opportunity for them to be innovative beyond expectation and uninhibited by the traditional limitations of cost.

Assessment

The Energy Efficiency programme was introduced initially using unit standards for assessment.

Energy Efficiency Unit Plan: Metal, year 13 , level 3 (Word, 316 KB)

Course outline booklet: NCEA 2013, level 3, achievement standards (Word, 444 KB)

The year 13 Energy Efficiency programme

Investigation and design

Within the year 13 Energy Efficiency programme, the students first investigate energy sustainability on a global level and then define what this would mean for their own home.

The students carry out an audit of the cost and usage of electricity, fuels, water, sewerage, and waste disposal to develop understandings of how the concept of sustainability applies in their own homes. They bring in their rates bills (which include costs for waste disposal, water, and storm water provision), water bills, and power bills.

Year 13 Technology, Metal: Sustainability – Energy Efficiency, Audit Checklist (Word, 197 KB)

Following the audit, the students come up with a plan to reduce energy costs in their homes.

Dave encourages the students to question their own living situation on a sustainability and cost basis to understand that it’s important as an energy consumer to recognise what you want versus what you need – and whether you are prepared to pay for it.

Some student families are now enjoying significantly lower monthly power bills as a result … and some have never forgiven me for turning their children into energy conservation nutters!

Dave Dobbin

The students then focus on hot water heating and use the design process to make a functional model of a solar water heating system to meet a brief.

Brief: Solar water heating model (Word, 39 KB)

Students are taught to interpret information from a sun path to determine optimal orientation (pitch, angle, and direction) for the day and time of the test race (when they will all test their models and see which one is the most efficient).

Sunpath: Auckland (PDF, 616 KB)

After the students have analysed their test results, they access the NIWA Solarview website to obtain sun path and energy data for their particular house address and use this in designing their full-scale solution for their home.

They research existing systems and have access to the students’ data from previous years. Tall systems have had quite a lot of success in previous competitions, so this year a couple of the students used this information to influence their designs.

Generic skills that are taught include the ability to plan, research, design, develop, commission, test, and evaluate a prototype’s fitness for purpose. Throughout this process, stakeholders are consulted – usually a parent as the homeowner for whom the full-scale solutions are being developed. This process builds upon the design processes taught at years 11 and 12.

Specific skill sets that are further developed include the research and selection of materials based upon material properties for each component of the system. Construction skills taught include glazing, systems for energy absorption, insulation, casing and framing, machining (including milling), guillotining, electromagnetic folding, tapping threads, MIG welding of frames, and finishing (including acid preparation, etch coating, and brazing of copper using Oxygen/Acetylene gas).

The students become proficient gas fitters having brazed complete functional systems, including the collector, circulation pipes, and hot water cylinder storage vessels, entirely from 0.5-0.71 mm wall thickness copper.

Racing

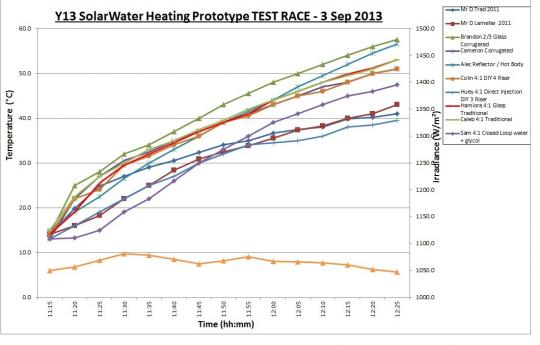

When their models are ready, the students race them against each other to see which is the best design and why.

The racing days are really exciting. They take a measurement every 5 minutes and record this on their spreadsheet. They often don’t want to say to their buddies next to them what their reading is! We enter the results on the spreadsheet using the data projector, and the students then graph the results. The students are totally engaged in seeing who had the better system.

Dave Dobbin

Year 13 solar water heating calculations and results (Excel 2007, 43 KB)

Evaluating and refining

Following the trials, the students spend 2 weeks working out why their system performed the way it did relative to their peers. Some of these discussions require high-level science understandings. For example, one of the systems developed this year was a closed loop system with a coil containing glycol. This student was trying to understand the heat transfer properties of glycol compared with distilled water. Dave encourages students to take up these discussions with their science teachers. There have been some interesting feedback sessions between the science and technology class, for example:

Sir, I need to find out the weight of my system as 1 ml glycol doesn’t weigh 1 gram – you know it has a different specific gravity to water!

Student

The physics teacher has helped some of the students to use their knowledge and development of their solar systems to submit evidence for the Achievement standard 91527 Use physics knowledge to develop an informed response to a socio-scientific issue.

The students’ solar water heating systems

In the first year of the programme, the students went on to build a full-scale solar water heating system for the school workshop – which is providing free hot water to the workshop every day.

In the second year, the students designed one for Whakatane Intermediate made of materials and involving construction methods suitable for year 8 students to construct in their hard materials programme. The class took a field trip to the Intermediate School to teach some year 8 students about solar water heating and to scope their environmental science building for the project.

During this full-scale solution design phase, students select specific engineering roles and sign a contractual job description that defines clear individual responsibilities within their team.

Year 13 engineer roles (Word, 59 KB)

They carry out research in accordance with their job descriptions then combine and debate the knowledge amongst their project team to form a final design solution proposal.

Student Alec Lilley designed a collector using a multiple mirror array that reflected sunlight onto a focused point on one side of the 1/2 litre water cylinder.

Alec's focussed point solar water heater parabolic mirror reflector array

Dave teaches the theory about all of the different systems that are available around the world such as evacuated tube, flat panel, line focus, and point focus reflectors, including typical DIY methods. Alec produced a very innovative solution based on point focus.

Brandon's aquarium system

Another two students asked if they could make an aquarium system – encasing the collectors in glass.

My response was I have never done that before. It carries a lot more risk (design, manufacture, installation, life cycle) but lets give it a go!

Dave Dobbin

One of the aquarium designs won the 70-minute race in 2013.

Teaching tools

Dave has a number of teaching tools that he finds effective in the programme.

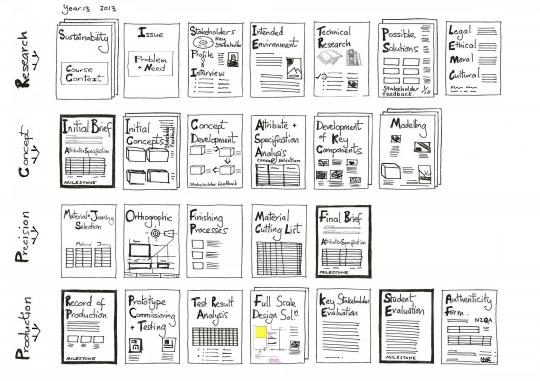

Colleague Nigel Rowland has developed a cartoon strip to depict the different design stages of a project. This approach is being used at all NCEA levels in Trident Technology courses. Teachers have found that the students engage with the cartoon strip much more than with programme planning instructions in words. Dave finds that the stages in the project evolve and can also be rearranged within a term. At a glance, the students can see scheduling in practice, discussing with Dave how to commit resources between a variety of possible tasks.

The cartoon strip has also been used in a pre-assessment sheet that Dave and Nigel have designed. The pre-assessment sheet is a running record that is used to record assessment feedback during periodic design portfolio hand-ins during the year. It outlines for the students where there are gaps in their evidence, where they are currently placed in terms of achievement levels, areas that need catching up on, and even their rank in the class. This has proved to be a very effective tool for both students and teachers to monitor progress towards achievement standards.

Outcomes

Student engagement

The students demonstrated their enthusiasm for the project this year by regularly attending the weekly after-school session offered by Dave from 3 pm to 9 pm for the entire second term.

Performance test results

Performance test results from this class exceeded those of the previous two years. From the average insolation (sun energy) level of 1064W/m2 the highest performing systems were converting this energy into hot water at a rate of up to 55% efficiency. Students have achieved this partly by learning from students’ results in previous years and by paying attention to a range of factors, including quality of fabrication to ensure high fluid flow rate, superior insulation, reduction in thermal mass, integrity of encapsulation to ensure minimal radiant and conductive heat loss, and ensuring accuracy of orientation to the sun.

The aquarium glass cased systems this year have smashed the previous record of 50°C by 7.5°C raising the Wattage to 23.4W (up from 20.2W) and at an efficiency of 55% (up from 50%).

This means that these systems are now performing at levels similar to the best solar water heating panels on the market. We certainly have a long way to go though on the cost of manufacture as the students cost calculations for their up-scaled full-system designs are proving prohibitively expensive compared to the commercially available systems on the market.

Dave Dobbin

For more information about the two winners of the 2013 solar power race, see Innovation in model solar power systems.

Employment

Four of the year 13 students have successfully gained apprenticeships during the two and half years this programme has been running, including one at a Kawerau Pulp & Paper mill, one at a sheet metal business, and another as a diesel mechanic.

The students often ask Dave to be a referee and feedback he has received from employers shows students knowledge and skills are appreciated and relevant.

Last week, I hired one of your former pupils as an apprentice in maintenance and diagnostics here at Norske Skog Tasman. He stood out from the 25 candidates across the BOP with the highest school marks and other prerequisites that we look for in a young person who wants a trade in heavy industry. This is a credit to him and also to your school, as young people who are passionate about our trade seem to be getting harder and harder to find.

Employer

With the confidence he has gained from implementing the Energy Efficiency programme, Dave sees himself supporting the year 11 and 12 students to become more diverse in their outcomes. Currently, they are mainly producing combustion engine outcomes such as go-carts and mini-motorbikes. However, students are now asking if other outcomes would be considered.

Dave also sees the potential for students and/or EBET to patent some of the innovative designs.

The system on my workshop roof is a corrugated iron system – a sheet of corrugated iron is removed from between the two purlins as a low cost retrofit solar water heating solution. This would be affordable for low-income home owners in New Zealand.

Dave Dobbin