Let's make cheese

Technology teachers often assume that cheese making is too complicated for a secondary school environment. Te Awamutu College has demonstrated that this is not necessarily so.

With support from Wintec, year 11 food technology students learned how to make a relatively simple cheese. They were able to gain NCEA credits for their achievement – and to learn a little about careers in the dairy industry.

Background | Building knowledge of cheese making | The project at Te Awamutu College | Science and cheese making | Cheese making and achievement standard 91047 | Purposeful testing in classroom settings

Background to the cheese-making project

Wintec’ s Centre for Science and Primary Industries and The New Zealand Cheese School Limited developed the Camembert in the Classroom science project pilot.

Wintec sponsored the two pilot schools, covering the costs of the starter kit, cheese-making kits for students, and teacher training. They also hosted the final judging of the camembert.

This initiative by Wintec was modelled on a similar project in Australia – focussed on introducing secondary school students to the many career opportunities available in dairy manufacturing.

See: Cows create careers camembert in the classroom module

Te Awamutu College was one of the two schools in the Camembert in the Classroom project pilot. The college incorporated the project into their food technology programme.

Building knowledge of cheese making

Before starting their projects, the students had a day at school – where they made a camembert.

Having a whole day set aside to complete a cheese helped the students take responsibility and manage making their own cheese variety. They knew cheese making was not just a one-hour class event and that they would need to make time to come back and process their cheese during the day.

Both of the teachers at Te Awamutu College had attended a Wintec and New Zealand Cheese School workshop, and had further grown their knowledge of cheese making through a Royal Societies Endeavour Fellowship and by attending a cheese-making workshop at Over The Moon.

The project at Te Awamutu College

Back at school, the students were asked to develop a feta cheese that could be part of a cheese platter for staff functions.

The students used a staff member as a stakeholder, developed their cheese concept, and then carried out three trials of their prototype. Processing time, temperature, methods, flavours, storage conditions, and storage time could all be varied in response to stakeholder feedback.

Because they were a member of the pilot programme, the school was supplied with cheese molds, mats, and starter kits.

The school purchased bain-marie pots for heating the cheese mixture. They have recently purchased a separate fridge for maturing and storing cheeses.

The project ran for a term and evidence from the project was used for assessment against:

Science and cheese making

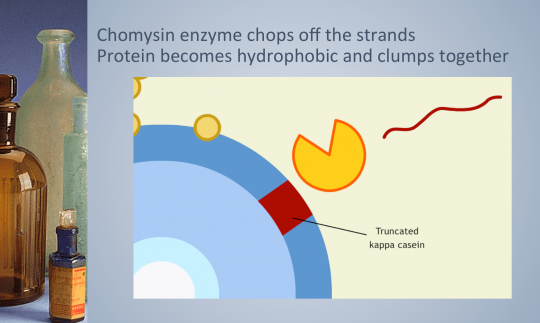

Cheese making requires a sound understanding of microbiology to ensure a quality cheese is produced that is authentic to its type.

The teachers included the relevant science knowledge alongside trialling so that the students could apply it as they made their cheeses.

Te Awamutu College: All about cheese (PowerPoint 2007, 1 MB)

A great way of reinforcing knowledge during practical sessions was asking questions, for example:

- What is the purpose of the rennet?

- Why did the texture change?

- What type of milk are you using and why?

- What are the proteins in milk?

- What is the liquid left from cheese-making called – what is this made of?

Cheese making also requires students to practice a high standard of food and personal hygiene to produce a successful outcome. This knowledge provides useful evidence for AS 91049: Demonstrate understanding of how materials enable technological products to function.

Cheese making and achievement standard 91047

A broad range of contexts can be used to assess prototyping – and cheese making is a good example.

When planning for teaching and learning that will be assessed against AS 91047, two things to be aware of are the following.

1. The brief needs to allow for a range of possible outcomes

Explanatory note 3 outlines the requirements:

The brief may be provided by the teacher or developed by the student. If the student develops the brief, then the teacher must ensure that it provides sufficient guidance to enable the prototype to be developed. The brief used for this standard must allow for a range of outcomes and include a conceptual statement and specifications for the prototype to be evaluated against

AS 91047, Explanatory note 3

Note the brief for this project at Te Awamutu College allows for a range of outcomes:

Cheese assessment student instructions (Word 2007, 31 KB)

Now that the teachers are more familiar with the cheese-making process, they plan to offer their next cohort the opportunity to make a greater variety of cheeses, which will allow for a wider range of outcomes.

2. There needs to be rigour around testing and trialling

Explanatory note 5 sets out the expectations:

A prototype is a finished outcome that is ready to be trialled in situ. It is developed through technological practice and is reflective of accepted techniques and tolerances, and safety and legal responsibilities. Prototyping is the trialling of the prototype to gain evidence for the evaluation of the outcome’s fitness for purpose in its intended physical and social environment.

AS 91047, Explanatory note 5

Purposeful testing and trialling demonstrate that a prototype meets the brief. See below for suggestions from a food technologist on managing purposeful food testing and trialling in classroom settings.

Purposeful testing in classroom settings

To achieve Merit and Excellence in AS 91047, students need to show that trialling has informed the development of their prototype and provided evidence of its fitness for purpose in its intended physical and social environment.

In this case, the prototype needed to be:

- acceptable to staff as part of a cheese platter

- safe to eat.

A food technologist's suggestions for manageable testing and trialling

To produce accurate data, sensory testing for a food product can be time consuming. In industry, food technologists may involve up to 200 people to ensure that the data collected gives accurate results.

Food technologist Carol Pound makes the following suggestions to make testing when cheese making authentic, but also manageable for a classroom setting.

- Students could determine the profile of a good feta cheese by interviewing a food technologist who makes feta. An alternative approach could be to find a small focus group that likes feta and ask them to describe what are the key 4–5 characteristics that profile a good feta (for example, creamy, salty).

- Students could carry out sensory testing by asking staff to compare their cheese with a popular commercially made cheese using their identified characteristics of a good feta cheese and hedonic scales.

- Limit the sensory testing. To gather meaningful data, 10 to 20 members of staff should try the cheese each time it is tested – this will take time to set up, conduct the tests, and analyse the results. Students could combine for this step so each staff member tests 3 or 4 cheeses.

- Consider testing for other product specifications. For example, yield, cost, texture (does the cheese maintain its shape to the extent it can be cut in pieces to serve attractively?), colour, product composition, shelf life, and what impact different processing times and methods have on these factors. In industry, products not only have to meet sensory requirements, they also need to be profitable and able to be manufactured.

- Students could also be assessed against AS91082 Implement basic procedures to process a specified product. This assessment could be carried out when they make a standard feta at the beginning of the project or at the end of their trialing. They will have established their own cheese-making process for their specified cheese with the associated testing.

- If the students have access to a cheese maker, they may be willing to carry out a hygiene audit on students’ processing equipment and environment and to carry out a contamination check on the cheese produced. The Safety in Technology guidelines suggest that pathogenic (disease causing) organisms should not be cultured at a school, so it would be advisable to carry out this food safety testing away from school.

For further information on testing in food processing in a classroom environment see: Testing in food processing.