Nests for the school production

Teaching inquiry

How could I use a request that we make some props for the upcoming school production as an opportunity to build my students’ understanding of technological modelling within practice?

Introduction

When Sally Laing of Coastal Taranaki School was approached to make some major props for the upcoming school production, she seized on this as an authentic context for teaching about attributes, functional modelling, and outcome development.

Sally found that through their work on the props for the school production, the students had opportunities to:

- explore modelling in technological practice

- evaluate an outcome against the key attributes in a brief

- understand that a pliable material can be turned into a sturdy product.

Background

Technology teacher Sally Laing of Coastal Taranaki School was delighted to be asked if she could arrange for three large “nests” to be made for the upcoming school production, To Be the Best. Each nest had to accommodate four “nesting” year 1 students.

Sally immediately recognised this as an opportunity for her year 6 students to create a technological outcome that would meet an authentic need. There was nothing available that they could easily copy or adapt, so they would have to develop their outcomes from scratch – using modelling in practice to determine a suitable size and structure.

Teaching and learning objectives

Sally planned to focus on the outcome development and evaluation component of technological practice. She planned to extend her students’ understanding of the technological modelling component of technological knowledge by branching into other contexts when the students had completed the nests.

For outcome development and evaluation, she selected this level 2 indicator:

- Describe potential outcomes through drawing, models, and/or verbally

Indicators of progression: Outcome development and evaluation

For technological modelling, she selected these level 2 indicators:

- Describe the sorts of things that functional modelling can be used for in technology

- Identify the design concept being tested in particular functional models

Indicators of progression: Technological modelling

Developing the brief

The producer of the school production came to the class and told the students the storyline, which was about encouraging students to be “the best that they could be”.

Three nests were needed for the production. Sally interviewed the producer to model the questioning process used for eliciting the required physical and functional attributes of an outcome.

For the nests, these attributes were:

- Each to fit four 5-year-olds

- Made to go on stage

- Able to be easily moved

- Safe

- Complete within four weeks

- To contain one thing a tramper might have left behind.

These attributes were gathered into a simple brief. The students would work in groups to create the outcomes.

Designing and making the nests

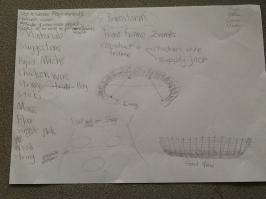

As a first step, the students researched nests for homework and shared their findings as a class.

Nests: Homework research (PDF, 19 KB)

Then they learned how to do a basic weave using sugar paper.

Surprisingly, the grandmother of one of the students had a collection of birds’ nests. The students were able to examine these, identifying the materials used by the birds, and how they were held together.

Sally created a presentation that included photos of different types of nests and man-made structures that owed their inspiration to nests. The class discussed the photos and the real-life nests collected by Zoe’s grandmother.

After using modelling to determine the required size of the nests, the students created the basic shapes from corrugated cardboard, taping and stapling the sides to circular bases.

They then punched holes in the sides and wove string in and out of the holes to provide a warp into which they inserted straw, flax, and other organic material to create the appearance of nests.

The students recorded the materials used and their performance properties.

Nests on stage!

Eventually the nests were ready to be put to the test. Because they were well made, they were easily transported to the stage without damage.

When we delivered the nests to the stage, it was like Christmas! The new entrants’ eyes lit up. The year 6 students assumed ownership of the nests and told the new entrants what they could and should do with them!

Sally Laing

The nests dried out a little over time, leaving a few bare patches, so the students gave the stage crew some spare organic matter to fill the gaps.

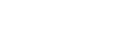

Once the class had finished their work for the production, Sally continued with the weaving theme by getting the students to make corrugated cardboard looms and then use them to weave a bookmark or tablemat. She was very pleased with the standard of the weaving and the students all got to take their little looms home.

As further weaving experiences, they made harakeke flowers and containers from aluminum cans (weaving jackets for the cans and adding wire handles).

Outcomes

The nests were a conspicuous feature of the school production – many parents and students commented favourably on them.

The students evaluated their outcomes against the key attributes to assess how well they had addressed the opportunity/need.

Modelling in technological practice

The project provided multiple opportunities for modelling in technological practice, particularly by means of discussion and actual models. These opportunities included the following.

Working out what diameter the nests needed to be

Initially, the students tied string around a group of four or five classmates sitting on seats, and drew around the group sitting on sheets of newsprint. When the new entrants came to class, they were smaller than the students had expected. The students repeated the exercise with the new entrants and found that the nests could be rather smaller than their original modelling suggested.

Testing whether the 2400 x 300 mm corrugated card strips from the storeroom would be suitable for forming the basic structure

The students tried this by wrapping the card around a group of five new entrants to see if it was long enough and whether they could step over it without tripping.

Discussions then ensued between the new entrants, the year 6 students, and the producer. The cardboard proved to be just right.

Sketching and brainstorming ideas

Testing ways of weaving organic material around the cardboard structure to give a nest-like appearance

Determining how best to allow for entry and exit

A gate was suggested, but this idea was discarded because it would require modifications to the script and a cardboard gate would be unlikely to last the distance. After further discussion, the students decided to leave a gap at the back of the nests.

Finalising the shape of the nests

Some modifications were made to the original concepts as the nests were being constructed.

Checking that the size of the nests and their position on the stage would be appropriate

Exploring weaving

One of the students used her cardboard loom to make mats for her dolls’ house and planned to go on and weave some furniture. Another student experimented with weaving wire into a badge. The students are now very aware that they can take a material that is pliable and turn it into something quite sturdy – like the nests.

What next?

Sally is now very interested in securing similar opportunities for future projects.

The energy generated by having a real need to address, with tight constraints, was great. Also, giving students the unexpected forced them to be creative and find solutions.

Sally Laing

Sally would like to grow her students’ understanding of technological modelling beyond practice. So she plans to explore modelling in other contexts and to develop a way of assessing what the students understand.